MDF cabinet door making cnc router

Feature of mdf cabinet door making cnc router

1. SYNTEC control system --- easy to operate and supports recover carving point after break or disconnecting power, with the function of forecasting process time.

2. Base frame --- welded with thick channel steel and square tubes, processing by high temperature tempering treatment and vibrating stress relief.

3. Beam and machine body --- integrated, good rigidity gantry with good performance against pressure and deformation, ensure the high precision,longevity and good stability。

4. Vacuum table --- with T-slot can not only suck the different size of machine, but also fix the irregular ones.

5. Limit switch --- prevent the mechanical impact cause by the improper files or operation.

6. Lubricating system --- lubricate every part of your machine by the processing time,it makes the maintenance more convenient.

7. Spindle --- 9.0 kw air cooling spindle.

8. Drill --- Italy 5+4 drilling.

Application of the mdf cabinet door making cnc router

Furniture: wooden doors, chairs,cabinets, stairs,computer tables, sewing machine, musical instruments

Plate processing: insulation, plastic and chemical, the PCB, move the car body, bowing, track, stars anti-special board, epoxy, resin, ABS, PP, PE, and other carbon mixture

Decoration industry: acrylic, PVC, MDF, artificial stone, plexi-glass, plastic, and copper and aluminum and other soft metal plate engraving and milling cutting.

It can make both cabient doors and panel furniture.

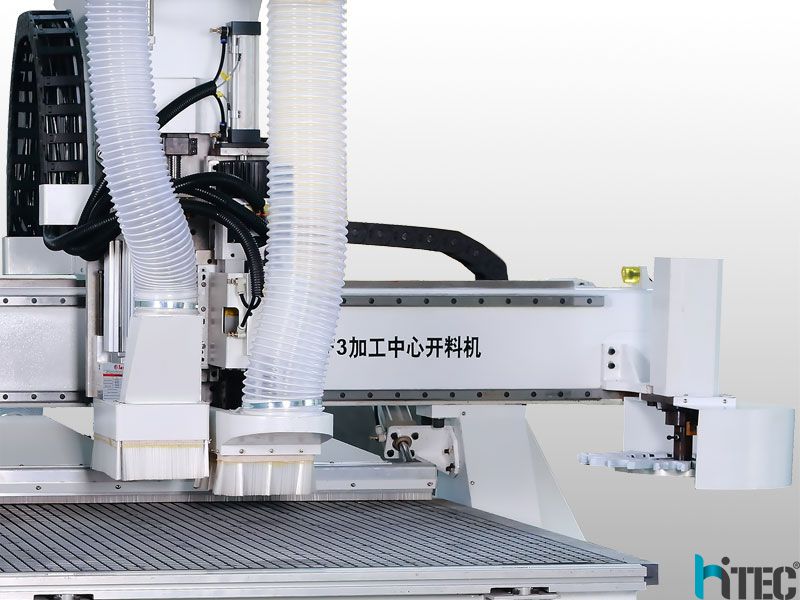

Details parts of the mdf cabinet door making cnc router

1.Circle tool magazine with 12 tool holders.

It is drived by servo motor, change tools only need 8 seconds.

The machine pop up pins is made of aluminum slot, the big contact sufface can make sure the small piece of the finished boards

will not fall off the table, The famous airtac cylinder could be adjusted to control the air quantity.

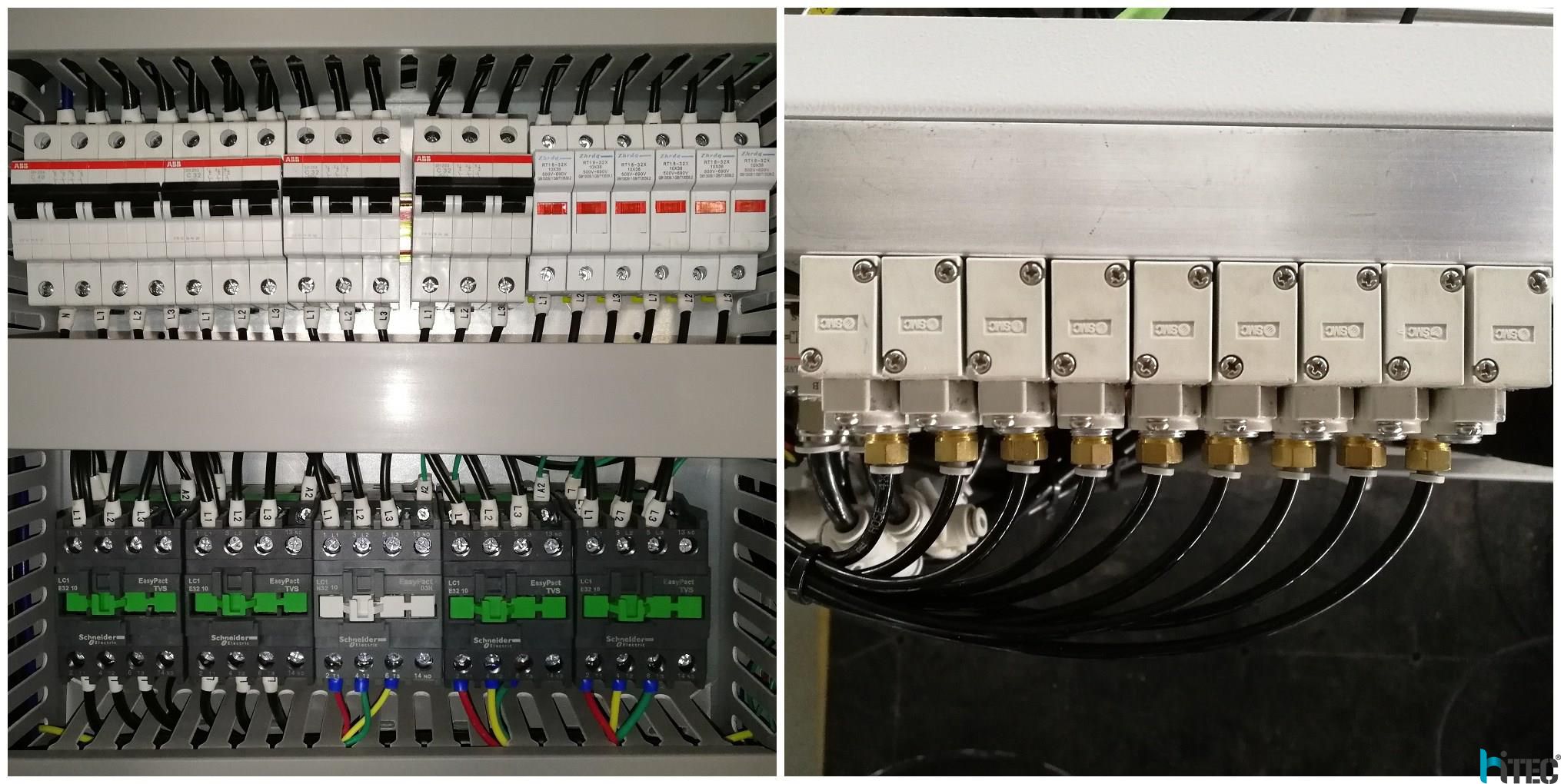

The machine electrical parts is made of Schneider and Japan SMC, they are famous on cnc machine part which can make sure the machine

good quality with long work life and high accuracy.

Other Advantage Parts

Parameters of mdf cabinet door making cnc router

| Brand | HITEC CNC® |

| X,Y Working Area | 1300*2500mm |

| Z Working Area | 200mm |

| Table Size | 1440*3040mm |

| Resolution | 0.01mm |

| Lathe Structure | Seamless welded steel structure, better than cast iron one |

| X,Y Structure | Rack and pinion, gear drive, Taiwan HIWIN square guide rails |

| Z Structure | Taiwan TBI rolling ball screw, Taiwan HIWIN square guide rails |

| Max. Idling Speed | 60m/min |

| Spindle | 9.0KW Italy Hiteco ATC air cooling spindle |

| Spindle Speed | 0-18000r/min |

| Working Voltage | AC380V/50Hz |

| Motor and driver | Japanese YASKAWA servo motor and driver |

| Command | G code |

| Operating System | Taiwan SYNTEC |

| Automatic loading and unloading system | (option)With Automatic loading and unloading system and Automatic loading and unloading table |

| Cooling Mode | Air-cooling |

| Dust-collect Function | Yes |

| Drilling head | (option)Italy HSD drilling head 5+4 |

| Price Range | 10000$-30000$ |

| Delivery time and payment | 1. 15-20 working days after get 30% payment by T/T; 2. Alibaba Trade Assurance. 3. Western Union 4. MoneyGramm |

| Payment terms | T/T, 30% in advance,the balance 70% should be paid before shipment. |

| Guarantee & After Sales Service |

1. One year quality guaranty. 2. Lifetime maintenance free of charge. 3. In our factory free training to guarantee you can operate machine correctly. 4. We will provide the consumable parts at an agency price when you need replacement after the warranty period. 5. 24 hours on line service each day, free technical support. 6. 24th service email 7. Machine has been adjusted before delivery. 8. Our staff can be sent to your company to install or adjust if necessary. |

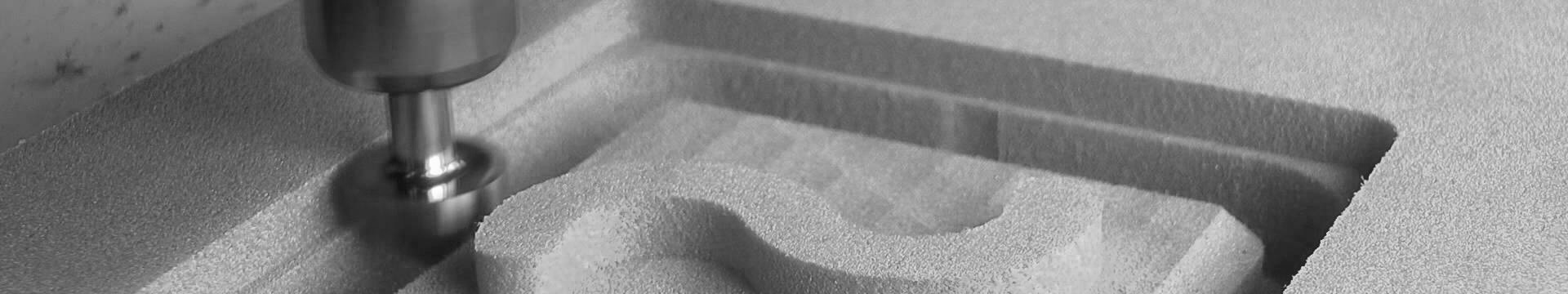

Samples of mdf cabinet door making cnc router

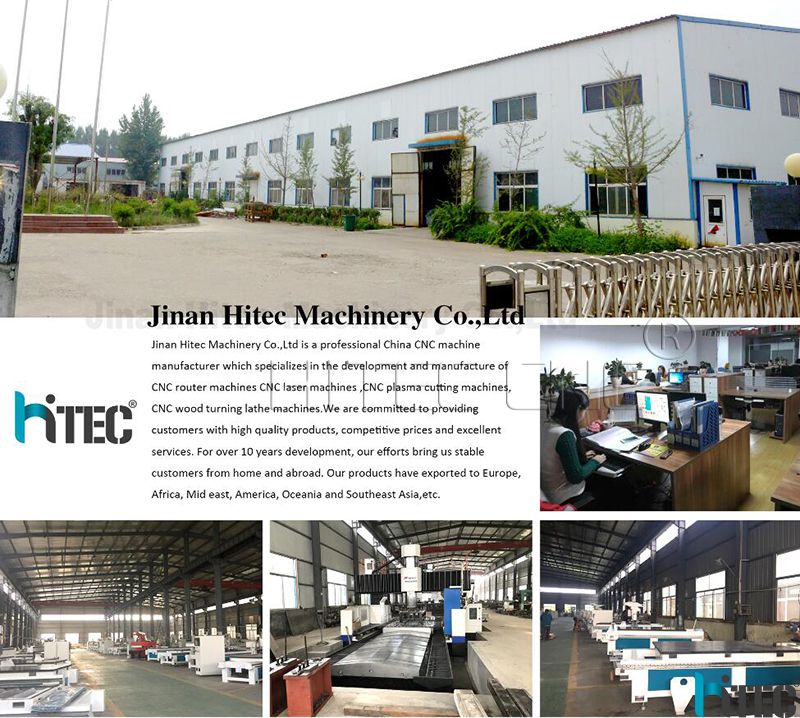

Our Hitec Company

Tag: MDF cabinet door cnc router mdf cabinet door cnc router cnc router cabinet door router cnc nesting router cabinet door cnc wooodworking cnc router