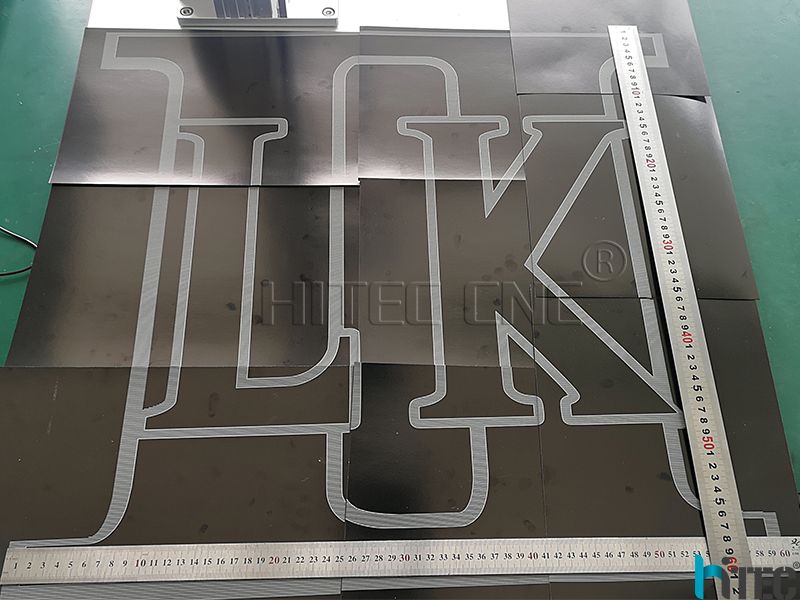

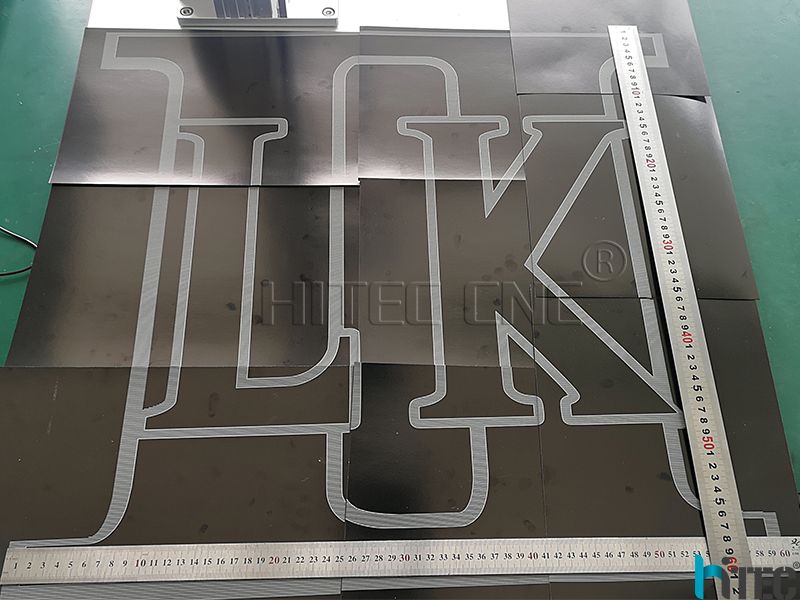

The 3D laser marking machine has greatly reduced the surface flatness requirements of the processed objects. In the process of deep carving, it not only ensures the effect, but also improves the efficiency, and the processable effect is more abundant.

3D Fiber laser marking machine advantage

1. Low operation cost, free maintenance for 3 years.

2. Marking speed: it enclosed 100w fiber laser marking machine uses a high-quality imported laser scanning equipment, speed up to 8000mm / s.

3. High Precision: fiber laser marking machines' repositioning accuracy of up to 0.002mm.

4. High-Rate of Electrical-Optical Conversion for the fiber laser marking machine: The efficiency of fiber laser marking machines optic-electrical converting is up to 70%.

5. High Reliability: MTBF(Mean Time Between Failures) >100,000 hours.

6. Integrated and Compact: Compact, Small, Desktop, Easy delivery

7. Easy Operating: English User Manual, VCD training video, software sending together with the fiber laser marking machines and 24 hours online service.

8. Air Cooling: fiber laser engraving machines adopts air cooling, which has excellent cooling effect than the other cooling method.

Marking Materials

Fiber lasers can be used for a wide variety of applications, from industrial traceability to branding, on materials such as steel, copper, aluminum, plastic, ceramic, and brass.