- Home

- About HITEC

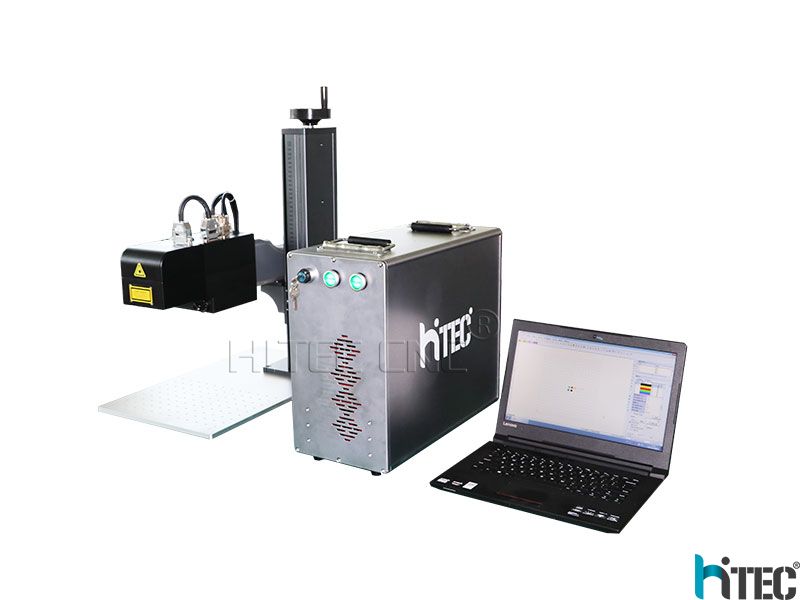

- Products

- Samples

- Videos

- Service and Support

- News

- Contact HITEC

| Basic | Software | EZCAD3.0 |

| Software Kernel | 64 bits | |

| Operation System | Windows XP/7/10,11 64 bits | |

| Controller Structure | FPGA for laser and galvo control, DSP for data processing. | |

| Control | Compatible Controller | DLC2-M4-2D |

| Compatible Laser | Standard: fiber Interface board for other types of laser DLC-SPI: SPI laser DLC-STD: CO2, UV, green laser... DLC-QCW5V: CW or QCW laser requires 5V control signals. DLC-QCW24V: CW or QCW laser requires 24V control signals. |

|

| Note: Lasers with some brands or models may need special control signals. A manual is needed to confirm the compatibility. |

||

| Compatible Galvo | 2 axis galvo | |

| Standard: XY2-100 protocol Optional: SL2-100 protocol,16 bit,18 bits, and 20 bits galvo both digital and analogical. |

||

| Extending Axis | Standard: 4 axis Control (PUL/DIR Signals) | |

| I/O | 10 TTL Inputs, 8 TTL/OC Outputs | |

| CAD | Filling | Background filling, annular filling, random angle filling, and cross filling. maximum 8 mixed fillings with individual parameters. |

| Font Type | Ture-Type font,Single-Line font,DotMatrix font,SHX font... | |

| 1D Barcode | Code11, Code 39, EAN, UPC, PDF417... New types of 1D Barcode can be added. |

|

| 2D Barcode | Datamatix, QR Code, Micro QR Code, AZTEC CODE, GM CODE... New types of 2D Barcode can be added. |

|

| Vector File | PLT,DXF,AI,DST,SVG,GBR,NC,DST,JPC,BOT... | |

| Bitmap File | BMP,JPG,JPEG,GIF,TGA,PNG,TIF,TIFF... | |

| 3D File | STL, DXF... | |

| Dynamic Content | Fixed text, date, time, keyboard Input, jump text, listed text, dynamic file data can be sent via Excel, Text file, serial port, and Ethernet port. |

|

| Other Functions | Galvo Calibration | Internal calibration, 3X3 point Calibration and Z-axis calibration. |

| Red Light Preview | √ | |

| Password Control | √ | |

| Multi-File Processing | √ | |

| Multi-Layer Processing | √ | |

| STL Slicing | √ | |

| Camera Viewing | Optional | |

| Remote Control Via TCP IP | √ | |

| Parameter Assistant | √ | |

| Stand Alone Function | √ | |

| Gradual Power UP/Down | Optional | |

| Gradual Speed UP/Down | Optional | |

| Industrial 4.0 Laser Cloud | Optional | |

| Software Library SDK | Optional | |

| PSO Function | Optional | |

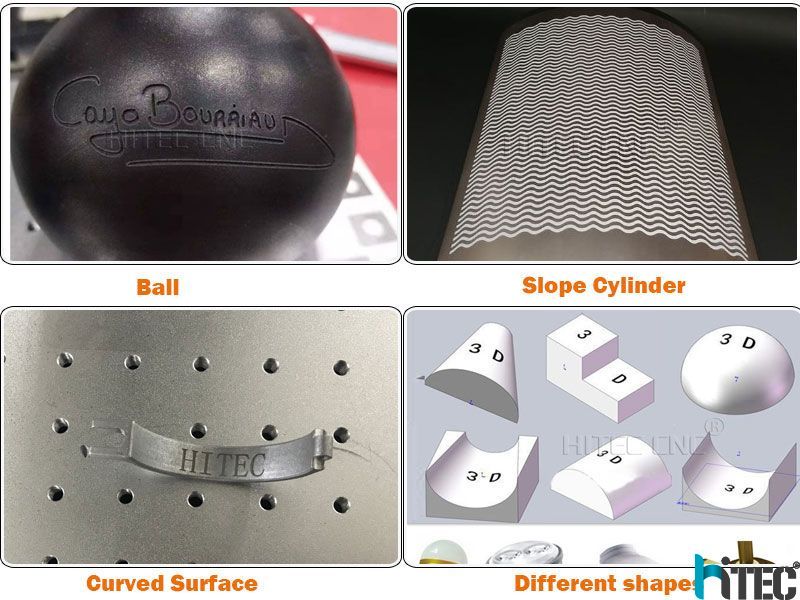

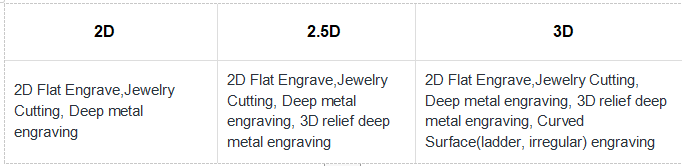

| Typical Applications |

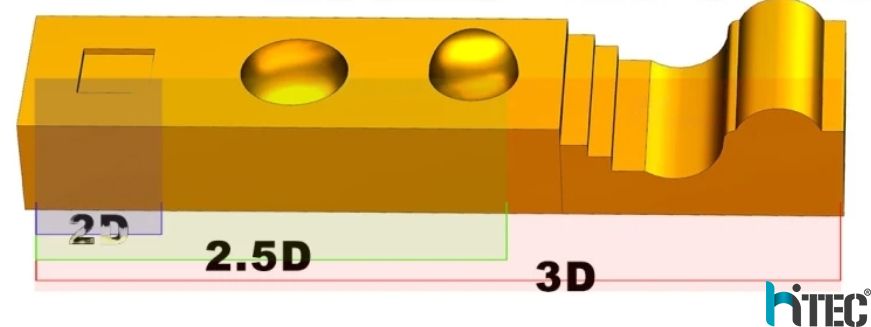

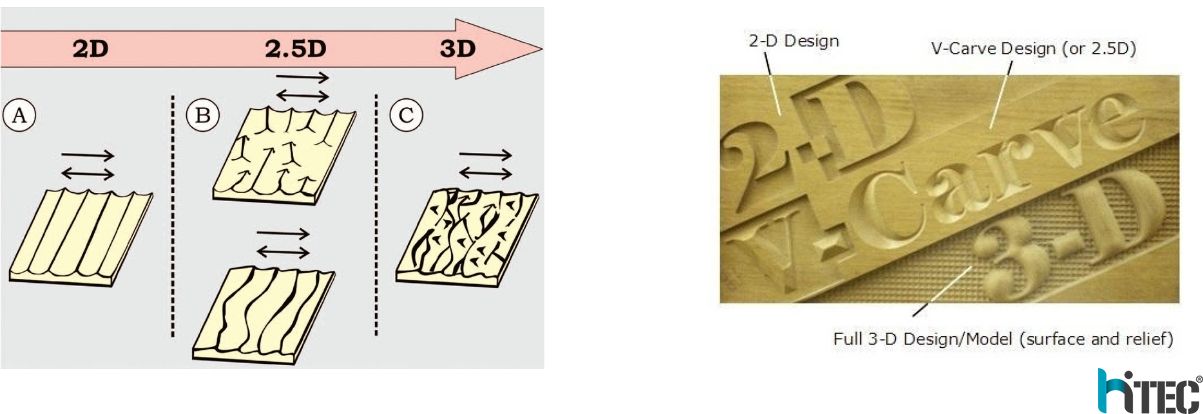

2D Laser Marking | √ |

| Marking on The Fly | √ | |

| 2.5D Deep Engraving | √ | |

| 3D Laser Marking | √ | |

| Rotary Laser Marking | √ | |

| Split Laser Marking | √ | |

| Laser Welding with Galvo | √ | |

| Laser Cutting with Galvo | √ | |

| Laser Cleaning with Galvo | √ | |

| other laser applications with Galvo. | Please consult our sales engineers. |

| Basic | Software | Lenmark3D LenMark_3DS |

| Software Kernel | 64 bits | |

| Operation System | Windows XP/7/10,11 64 bits | |

| Advantage |

Compatible Controller | FEELTEK |

| The self-developed LenMark software is specific for dynamic focus control. The 3D interface is easy to operate, can import 3D images directly, edit and map, quickly realize the 3D surface accurate processing control. | ||

| Description |

Support import of kinds of vector files and bitmap files. Support network port, serial port data reading, can facilitate automatic production line data interfaction. Self-developed software,support further development. Optimization for application,open interface,can be customized to requirement. Support multi correction methods:fast and high precision correction on high precision ideal platform and free adjustment of each position focal point under the non-ideal plane,and finally achieve full format focus consistency. Support 3D application,support importing of STL model, self-developed model, etc. Support 3D data editing rapid realization of 3D surface marking,relief processing. Support expansion of 3D scanning requirement,it can realize the rapid localization and reverse processing of 3D workpieces,and the rapid marking of workpieces can be realized without the workpiece model. |

|

| Engraving | Projection Positioning | |

| Platform moving line | 3D surface marking | |

| 360°rotation marking | Customization | |