CNC Oscillating knife cutting machine cut Evafoam, Polyester Fiber

Application of CNC Oscillating Knife Cutting Machine

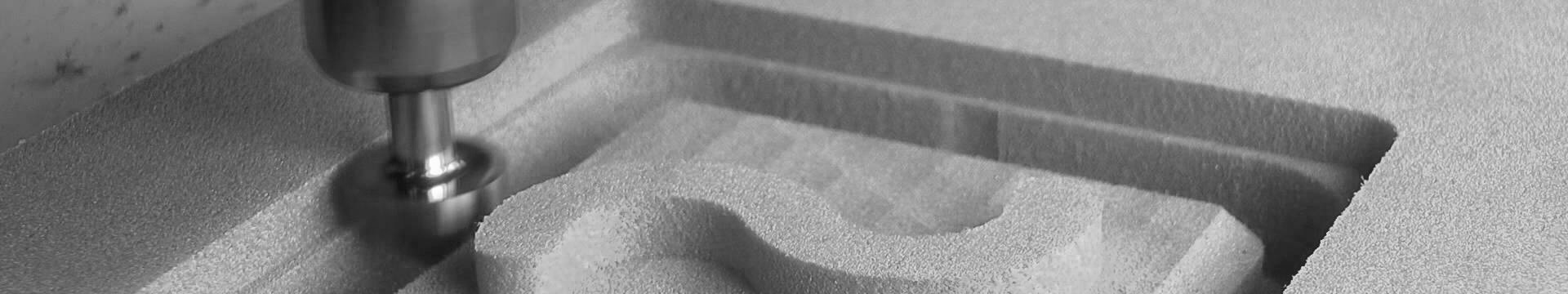

Cnc Oscillating Knife Cutting Machine popular for Evafoam polyester fiber ,is professional in leather cutting, especially for genuine leather cutting. It can be widely applied to industries as footwear, shoes, garment, hat, gloves, bags and wallets, belts, chairs, furniture, etc.

Besides genuine leather, this cutting machine is also very capable of cutting some other soft materials, such as: PU, faux leather, cloth, Oxford fabric, PVC, rubber, EVA, even shoes insole, and so on.

Features

1. HITEC Series foam board cutting machine is a multi-functional digital cutter that meets a variety of needs.

The modularized tool head structure enables convenient tool-switching and provides economical future upgrading.

2.The digital cutter's six axis motor-controlled CNC system performs with high speed and accuracy.

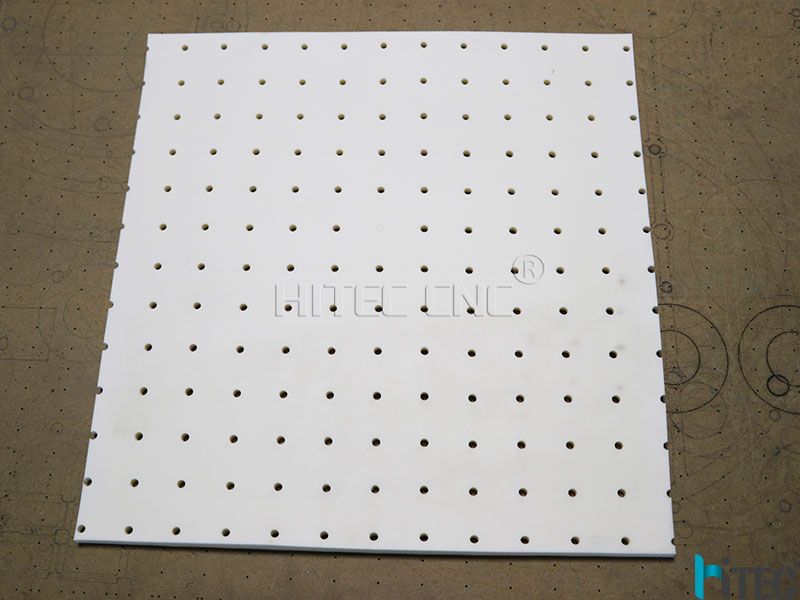

3.The DSP integrated controller reduces the error rate and maintenance cost while the divided-section vacuum system offers satisfactory and controllable suction. The Ethernet port, user-friendly interface allows design software from different PCs access to one cutter which maximizes your investment.

4.The LCD touch screen panel makes it easy to learn and operate.

5.The digital cutter offers flexible tool module options that meet the requirements of diverse industries.

6.The digital cutter is a CE certified product.

Optional Parts

Osillating tools

Pen

Cursor position

Foam cut (for option)

V-cut (for option)

Drag blade (for option)

Router tool

Eva Foam Cnc Oscillating Knife Cutting Mahcine Parameters

| Model | HTO1625 | HTO1825 | HTO2030 | Accept special model customization | ||

| Effective working area | 1600x2500mm | 1800x2500mm | 2100X2500 | |||

| Multi-head optional | Double head optional efficiency doubled, double gantry optional, double head mutual shift optional, length can be customized | |||||

| Multi-function tool | Vibrating knife full cutting, high power active round knife, punching tool, pneumatic knife, multi-layer knife | |||||

| safety devices | Safety devices use infrared sensing, safe and reliable | |||||

| Cutting speed | 200-2000mm/s | |||||

| Cutting thickness | ≤50mm Other thicknesses can be customized according to the material | |||||

| Applicable materials | Glass fiber, glass fiber cotton, prepreg, carbon fiber, carbon fiber felt, boron fiber, aramid fiber, ceramic fiber, soft glass, PVC, leather leather, sponge composite skin, XPE material, wire ring, leather, soft glass , silicone, rubber material etc composite soft material | |||||

| Material fixing method | Vacuum partition adsorption | |||||

| Transmission port | Network port | |||||

| Transmission system | Yaskawa servo motor, linear linear guide, timing belt, lead screw | |||||

| rated power | 11kw | |||||

| Rated voltage | 380V±10%/220V±10% Optional | |||||

| Control System | Chinese and English LCD touch screen | |||||

| Operating environment | Operating environment Temperature 0-40°C Humidity 20%-80%RH | |||||

| Software | Automatic nesting software, template entry software(Optional) | |||||

| Support file format | AI、PLT、DXF、CDRetc | |||||

| Overall size | 3570x2290x1165mm | 3570x2500x1165mm | 3570x25800x1165mm | |||

Application Projects

Main Parts of Cnc Oscillating Knife Cutting Machine

Cnc Knife Cutter Wooden Package

Appropriate packaging process:

1. After strict quality assurance process control together with quality inspection, qualified cutting machine is ready to transport.

2. Film packaging is a must to forbid humidity & damage.

3. Wooden case package is another secure guarantee.

4. Reliable containers and freight forwarder is another key point.

5. Arriving safe and sound on time

FAQ

Question: Do you accept customized products?

Answer:: Yes, our vibratory knife cutting machine cutting machine is steady and reliable.

Question: Do you have user manual book ?

Answer: Yes, user manual at present is written in English. We also provide on-site installation and training service is required. There is no special requirement for operator, operating is easy.

Question: If i place order today, when can i get my cutting machine?

Answer:: It depends on two factors: transportation time and manufacturing time. We are near to the sea port and train station, lead time is short. Manufacturing is made according to order shift, usually qualified product can be finished within 7-25 days. Transportation time depends on the distance between you and the sea port. You can ask for our advice or from the freight forwarder.

Tag: Evafoam cnc oscillating knife cutting machine flexible polyurethane foam cnc cutting machine polyester fiber cnc cutter machine cnc oscillating knife cutter cnc oscillating knife cutting machine