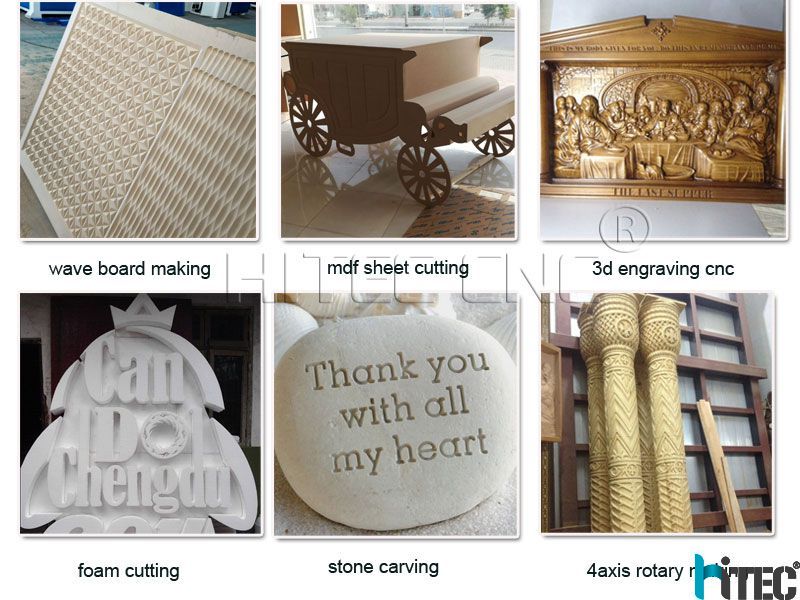

2040 Worktable CNC Router with Automatic Tool Change

This 2040 ATC CNC routercan automatically change 8 pcs tool bits one by one.

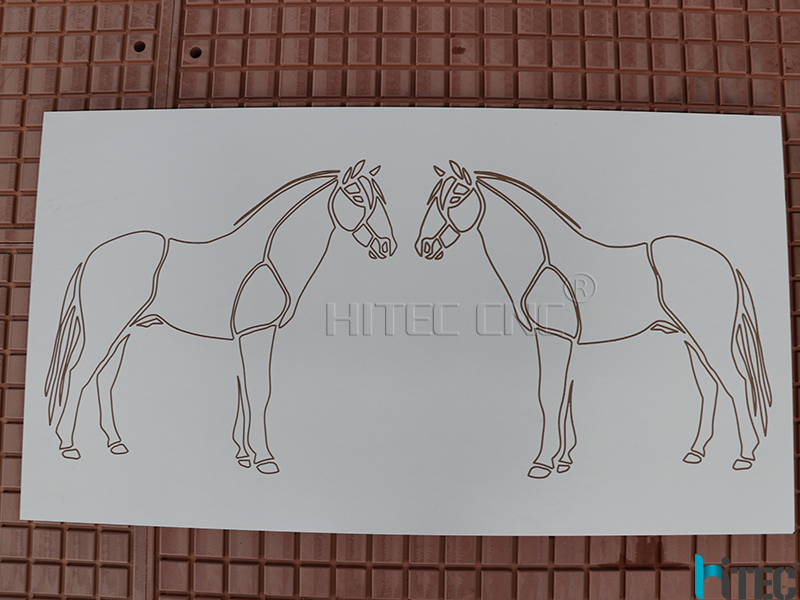

The customer makeone required design by one CAM software on your computer, then turning theminto cut patterns for the machine.

Arrives pre-built with correctalignment. No complicated set-up process.

This industrial cnc router machine runs on 220-volt3-phase -60-hz power.

Powerful 12hp spindle cantackle soft-metal perfectly.

9 kilowatt air-cooling spindle will stay accurate through years of production.

Variable spindle speed, from 0 to24,000 rpm.

High Torque Servo motor sensure smooth running at both fast and slow speeds.

300mm High gantry working area is up and away from material,can process the 2mm-250mmthickness material.

Y axis moves far enough for the gantry to clear the table. You can take the material directly off; no need slantit awkwardly.

Upload your design to the table with a USB drive. Automatic tooling changes let you swap out bitswith computer-controlled precision. Sensor compensates for the change in tool lengths. That change might seem tiny, but it makes a huge difference to the finished product.

Pre-load up to 8 colletors with your chosen profiles; the router will switch between them as programmed.

Powerful 10hp vacuum pump in the bed of the wood router machine holds the material in place during the cutting process.

6 vacuum zones allow you to turn on the valve only for the area where you’re working.

Arrange each zone’s vacuum seal into the shape of the material to provide well-distributed suction.

Dust shroud fitsover the spindle; you can vacuum out all the dust and chips while you’re cutting.

Fully-welded steel frame keeps the machine stable, helping the router last longer andpreventing vibrations from taking the cut off-course.

Parameters

| Brand | HITECCNC |

| Spindle | 9 Kw ER32 Standard Quality Air Cooled. Optional Upgrade HSD ATC Spindle up to 12 tools. |

| Working Table | TSlot & Vacuum table 5.5 kw air cooling vacuum pump. Optional Upgrade Becker KVT 3.140 129 m³ vacuum pump. |

| Control System | Syntec Control system. |

| Machine Body and Gantry | Heavy duty metal welding, quenching and sandblasting. Twice painting. |

| Driving system | 850 W servo motor and driver. |

| X, Y Axis Structure | 1.25M helical rack and pinion drive. |

| Z Strucutre | TBI ball screw. |

| X Y Z Axis Square Rails | 25 Square Rails. |

| Inverter | 5.5 Kw |

| Electric Parts | France Schneider |

| Limited Switch | Japan Omron |

| Machine cable | German Siemens OEM factory cable |

| Oil Lubrication | Hand control with Aluminum oil pipe |

| Machine Max Travel Speed | 9.84 ft/min |

| Machine Max Working Speed | 6.56 ft/min |

| Machine Voltage | 220 V, 60 Hz |

| Machine software | Artcam |

| Assist Loading Roller | Yes |

| Control Switch | German Moeller |

| Dust Prevention System | Woolen Blanket Square Rails Clean |

| Machine Head Board | Aviation Aluminum Alloy Thickening |

| Other Optional | Dust collector Mist Cooling Pump Servo Motor Italy HSD Spindle |

| Price Range | 12000$-28000$ |

Details Parts

Tag: cnc router 2040 cnc router cnc router with automatic tool change