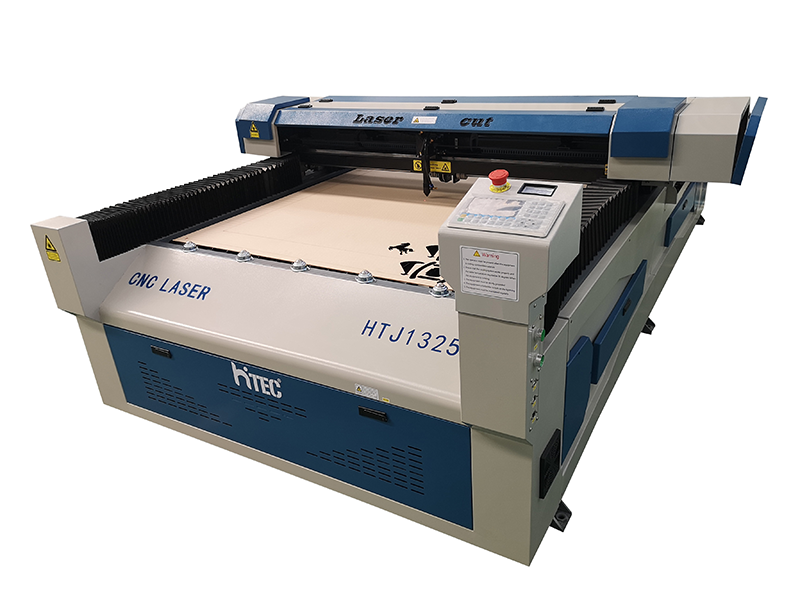

High quality co2 laser cutting machine for acrylic, wood, mdf, pvc, fabric, leather, rubber

Co2 laser cutting machine features

*Application: Laser Cutting Condition: New Laser Type: CO2

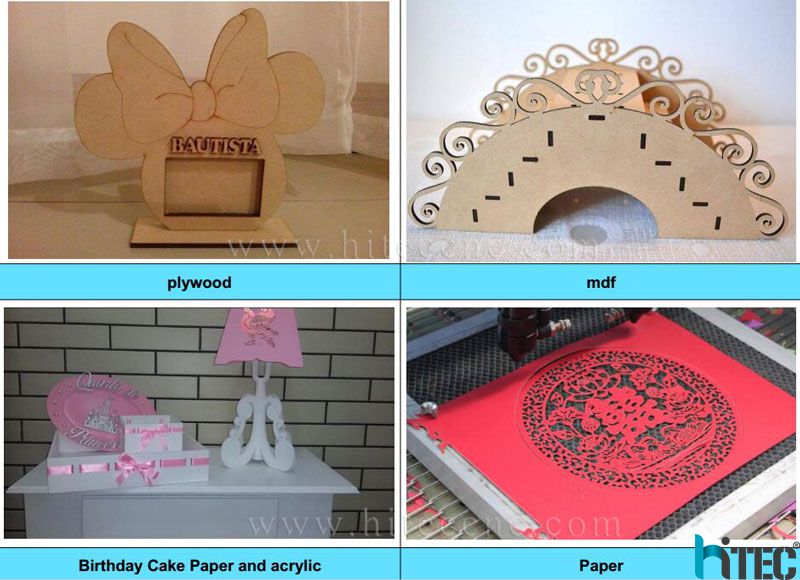

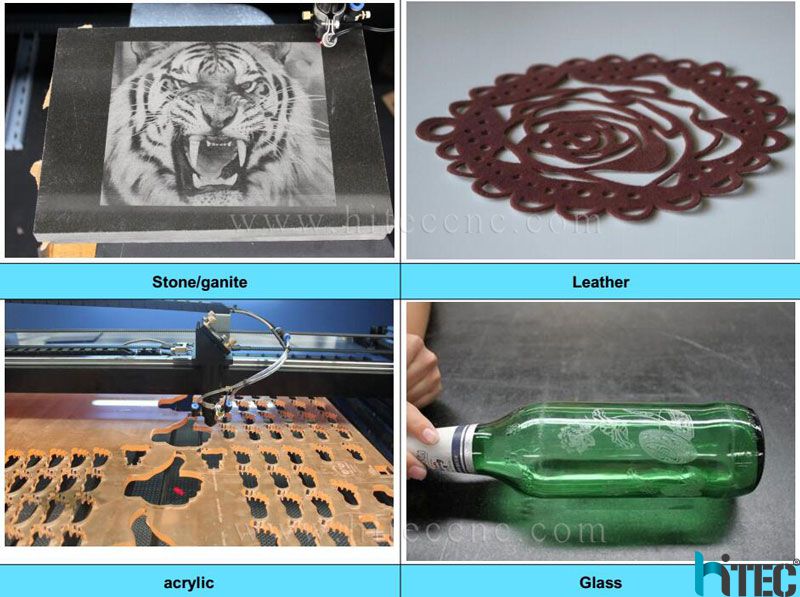

*Applicable Material: Acrylic, Crytal, Glass, Leather, MDF, Metal, Paper, plastic, Plexiglax, Plywood, Rubber, Stone, Wood

*Cutting Thickness: According to the different materials

*Cutting Area: 1300X2500mm Cutting Speed: 0-40000mm/min

*CNC or Not: Yes Cooling Mode: Water Cooling

*working area :1300X2500mm

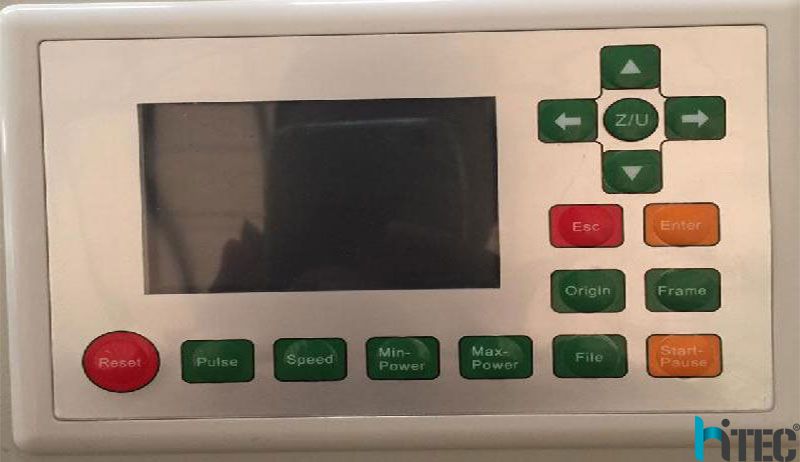

*Control system: RD-6442S

*Taiwan Hiwin linear square Rails

*Laser power : 150W Reci brand laser tube(best in china)

*Red-light Pointer

*Leadshine stepper motor and drivers

*Dust collector system

*Air pump

*water chiller 5200 Cooling systerm

*Exhaust Fan

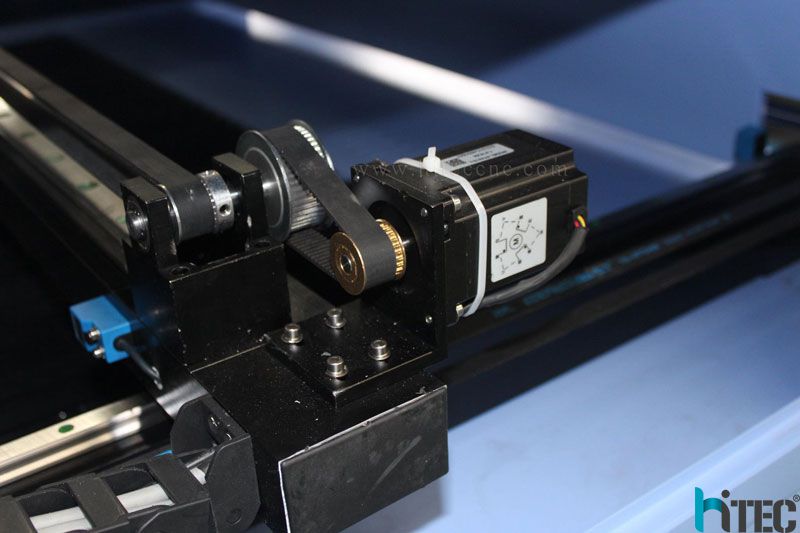

*Taiwan Fulong Belts

*Singapore Lenses and mirror (3 mirror and 1 lenses )

*Blade table

*standard tools box

*USB offline

*water protection switch

Parameters of the co2 laser cutting machine

| Product model | HTJ4060 | HTJ6090 | HTJ9125 | HTJ1612 | HTJ1325 |

| Max working area(mm) | 400*600 | 600*900 | 900*1250 | 1600*1200 | 1300*2500 |

| Gross weight with accessories | 240kgs | 280kgs | 320kgs | 400kgs | 900kgs |

| Laser power | 60W/80W/100W/120W/150W/180W | ||||

| Laser Types | Hermetic And Detached CO2 Laser Tube | ||||

| Engraving speed(mm/min) | 0-75000 | ||||

| Cutting speed(mm/min) | 0-40,000 | ||||

| Minimum letter | English 1 x 1mm | ||||

| Location precision | ≤0.01mm | ||||

| Resetting positioning accuracy | 0.01mm | ||||

| Driving system | Stepper (Hybrid servo&Panasonic servo are optional) | ||||

| Software | Lasercut 5.3 or RDworks V8 (because we have two kinds control cards for you choose | ||||

| 360°slope engrave | Yes | ||||

| Power supply | AC 220V/50Hz~60HZ (110V is also available) | ||||

| Operating temperature | 0 - 45℃ | ||||

| Operating humidity | 5 - 95% | ||||

| Laser output control | 1-100% control panel and software setting | ||||

| Highest scanning precision | 50-1000DPI | ||||

| Compatible software | CorelDraw, AutoCAD, Photoshop | ||||

| Auxiliary Devices | Exhaust fan and Exhaust pipe | ||||

| Cooling mode | Water-cooling and protection system | ||||

| Price Range | 5000$-8000$ | ||||

Samples

Detail parts of the co2 laser cutting machine

1.Laser head and belt transmission by Taiwan best quality Fulong brand

2.Reci 150w laser tube,longe lifetime 1000hours

3.RUIDA RDS6442 Control systerm

4.Leadshine steeper motor and drivers

5.Co2 laser cutting machine control box

6.High quality co2 laser cutting machine for acrylic,wood,mdf,pvc,fabric,leather,rubber

Selecting your Laser Cutting Machine?

Before you start calling companies and making your decision on who you are going to go with, you should know the basic questions and answers that are required to make sure you are getting the right laser cutting machine for your workshop.

1. What kind materials will you need to cut?

Depending on the type of materials that you are cutting with decide what kind of laser is required. If you are only cutting thin metals than a fiber laser will be more efficient, though if you are cutting plastics or woods then you will need a CO2 lasers. (There are material restrictions on each laser source)

2. What is the common size of sheet metal that needs to be cut?

This will determine the size of your cutting bed also be sure that you will have enough room in your workshop to fit. Common size for laser cutting is 1.5m Width by 3m Length.

3. What is the thickness of the material do I need cut?

The thickness of the material will determine the power of the laser source, as the thicker the material the more power is needed to be supplied.

4. Do I need CAM Software?

Every machine is equipped with computer controlled laser software. CAM Software is a very important piece of software for your machine, it will give you the ability to easily operate your machine and provides you with nesting capabilities to save you on consumables and materials with its intelligent design.

5. What are the cutting speeds?

The speed of machine will vary depending on the size of material that is cut, though the speed of the cut will give you the effectiveness of the machine you are purchasing and is both determined by the laser source you will be using and the machines capability.

6. What do I need in my workshop?

Before you purchase a machine you need to look at a few factors in your workshop, firstly if you have the space for the laser machine, secondly if you have the power in your workshop to handle the machine (ask a Farley rep for the floor area and power required).

7. Is there a local service team?

There is less problem for laser machine, most are operation problem - our engineer provides on-line training; any technical question, they can resolve on-line or by remote-assistance. HT engineer is available to visit your factory and provide face-to face assistance or training. There are 13 engineers in HTJ Laser to help foreign customers and domestic customers.

If you have the answers to these questions then you will be able to select the correct laser cutting machine for your workshop

Tag: C02 Laser cutting machine laser cutting machine price acrylic laser cutting machine leather cutting machine