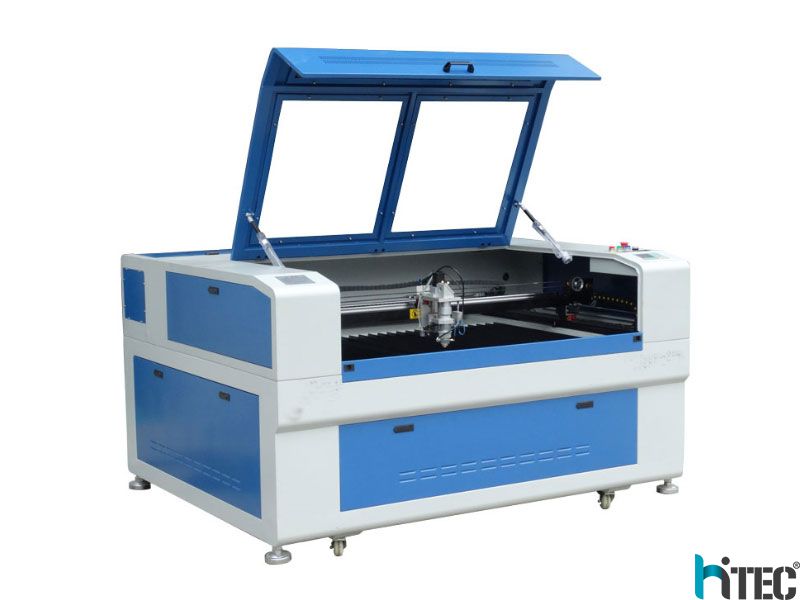

laser cutting machine manufacturers&suppliers

Application of the laser cutting machine manufacturer

Materials ♦

with co2 laser tube,can be used for cutting metal sheet such as carbon steel,stainless steel and nonmetal materials such as acrylic,die board,MDF,plywood,etc.

Applicable materials: acrylic, stainless steel, carbon steel, MDF,die board.

Applicable show: metal spectacle frame, furniture plate cutting, MDF photo frame cutting, building model cutting.

Applicable materials: acrylic, stainless steel, carbon steel, MDF,die board.

Applicable show: metal spectacle frame, furniture plate cutting, MDF photo frame cutting, building model cutting.

Technology ♦

CO2 laser

Associated function ♦

engraving,cutting, marking, identification, traceability

Other characteristics ♦

compact, economical

X travel ♦

1300 mm

Y travel ♦

900 mm

Cutting speed ♦

55 m/min

Laser power ♦

Reci 150W

Laser cutting machine manufacturer Features

1,Mixed-cut:metal-Stainless steel,carbon steel and non-metal-acrylic,board .

2.High precision motor with imported belt tansmission greatly improve the response speed and cutting precision of equipment, extend the time of using

3.High precision and Good stability :With precision ball screw transmission mechanism and optimized the nc system control, it can meet the precision parts processing, stable dynamic performance,also can work for long hours.

4. The cutting section with good quality:Mechanical follow-up cutting head system, cutting head always follows the material to keep the cutting point location unchanged, which insures smooth cutting section without processing again. It can adapt to flat or curved surface sheet cutting.

5.Adopt sealed co2 laser tube,main consumable items are electric energy,water-cooling, auxiliary gas and laser light.

6. Sample structure, easy operation, stable laser device and low maintenance cost.

Parameter of the laser cutting machine manufacturer

SamplesCO2 laser

Associated function ♦

engraving,cutting, marking, identification, traceability

Other characteristics ♦

compact, economical

X travel ♦

1300 mm

Y travel ♦

900 mm

Cutting speed ♦

55 m/min

Laser power ♦

Reci 150W

Laser cutting machine manufacturer Features

1,Mixed-cut:metal-Stainless steel,carbon steel and non-metal-acrylic,board .

2.High precision motor with imported belt tansmission greatly improve the response speed and cutting precision of equipment, extend the time of using

3.High precision and Good stability :With precision ball screw transmission mechanism and optimized the nc system control, it can meet the precision parts processing, stable dynamic performance,also can work for long hours.

4. The cutting section with good quality:Mechanical follow-up cutting head system, cutting head always follows the material to keep the cutting point location unchanged, which insures smooth cutting section without processing again. It can adapt to flat or curved surface sheet cutting.

5.Adopt sealed co2 laser tube,main consumable items are electric energy,water-cooling, auxiliary gas and laser light.

6. Sample structure, easy operation, stable laser device and low maintenance cost.

Parameter of the laser cutting machine manufacturer

| Model | HTJ1390 Laser cutter for metal and non-metal |

| Working Area | 1300mm*900mm |

| Working Table | Blades |

| Working Speed | ≦600mm/s |

| Laser Type | Sealed co2 laser tube |

| Laser Power | 150W |

| Positioning Accuracy | ±0.05mm(without red dot) |

| Image Format Supported | BMP,PLT,DST,AI,DXF,etc |

| Cooling System | Constant temperature water cooling and protecting system |

| Power Supply | AC220±10%,50-60Hz,30A max |

| Working Temperature | 0-45℃ |

| Working Humidity | 5%-95% |

| Smoke Exhausting | By Funnel |

| Auxiliary Cutting Gas | Nitrogen,Oxygen or Air |

Hitec group professional manufacturer for laser cutting machine

Tag: laser cutting machine manufacturer laser cutting machine supplier laser cutting machine laser cutter machine