Fiber laser cutting machine price

KEY FEATURES

► High efficiency

► Low energy requirement

► High cutting ability in all kinds of materials

► Low material consumption

► Low maintenance requirement

► High speed cutting

► High Beam quality

► Modular design

► Increase production with FlyCut and FastCut technology.

Fiber laser cutting machine advantage

1. The machine flat part construction is based on the type HTF-1530T with a drive in the form of a combination of servomotors and the system of a rack and a pinion. This system allows reaching high precision of 0.05 mm and high speed as well as allowed accelerated speed of 1.5 G. The advantages of this combination are reflected mainly in the processing of shape-demanding objects, as the work efficiency is higher by up to 40 %, compared to the M-series. The device is equipped with a fixed table with a working area sized 3,000 x 1,500 mm.

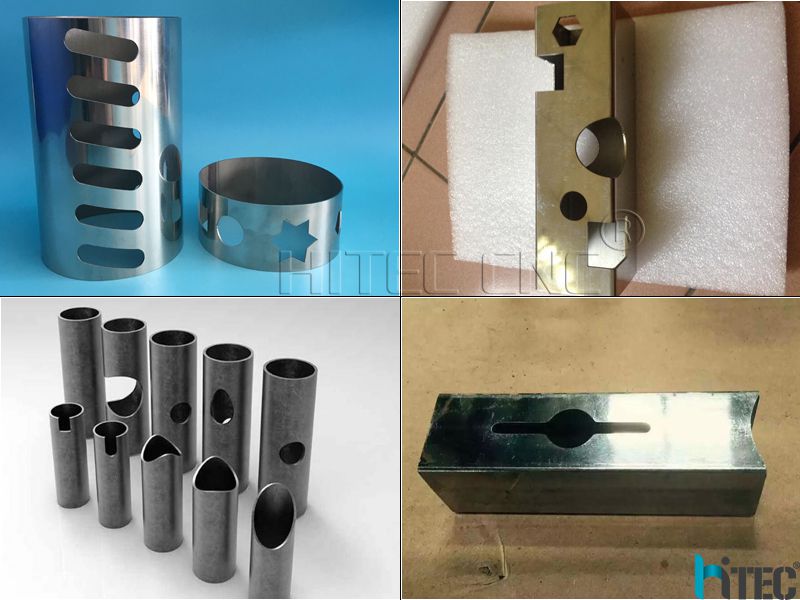

2. The other part of the machine is designed for processing sections with a length not exceeding 3,000 mm and a diameter of 150 mm. It uses an extremely precise principle of a tube laser: the material is fed through the rear chuck in a precisely controlled trolley through the front chuck as far as under the cutting head. Both the chucks of this machine version are supplied in a mechanical design.

3. The fiber laser cutting machine is controlled by two programs: CypCut - for 2D cutting, and CypCut Tube for section cutting. Source data for surface cutting are imported in the most common format .dxf, which can be generated from a variety of software programs. Data for section cutting are then loaded in the format .iges. To prepare data for section cutting, the software Solidworks is highly recommended; the manufacturer guarantees its full compatibility. We supply both the programs for laser cutting with two licenses; one is installed directly in the machine, whereas the other is intended for possible data preparation outside your device.

Applicable Industry

Sheet metal, hardware, kitchenware, electronic, automotive parts, glasses, advertising, craft, lighting, decoration, jewelry, furniture, medical device, fitness equipment, oil exploration, display shelf, farm machinery, bridge, ship, structure parts, etc.

Applicable material

Carbon steel, stainless steel, galvanized steel, alloy, titanium, aluminum, brass, copper, round, square, rectangular, oval, waist round tube and other metal sheets & tubes.

Parameters of fiber laser cutting machine price

| Brand | HITEC CNC® |

| Laser Type | IPG / Raycus Fiber Laser Generator |

| Laser Wavelength | 1080 nm |

| Laser Output Power | 750W / 1000W / 1500W / 2000W / 3000W / 4000W / 6000W |

| Laser Head | Raytools cutting head |

| Max Cutting Speed | 0-700mm/s |

| Position Accuracy | <±0.01mm |

| Driving System | Japan YASKAWA Servo motor and drivers |

| Transmission | Taiwan HIWIN Linear Rail + Germany ATLANTA Gear rack |

| Reducer | France Motoreducer |

| Electric parts | France Schneider |

| Acceleration | 1.5G |

| Working table max loading | >1000kgs |

| Warranty | 3 years |

| Power Adjustment | 0-100% controlling, (0-100% adjusting by software) |

| Aiming Position | Red-light position |

| Blowing System | Cabinet exhaust fan |

| Minimum Character | Chinese character 2.0mm, crisscross-row 1mm |

| Working Environment | Temperature: 0-45°C, Humidity: 5%-95% |

| Noise | <65Db(not include exhaust fan noise) |

| Lubrication system | Auto |

| Software | CYPCUT |

| Graphic support | AI, BMP, PLT, DXF, DST, etc |

| Protection level | IP54 |

| Working Voltage | 380V; 50Hz/60Hz |

| Stabilizer | 30---80KVA (option) |

| Machine whole power | 10KW |

| Machine weight | 5 Tons |

| Price Range | $3,0000-$8,0000 |

Details Parts

NO.1 Our Factory And Quality Control

Quality is our paramount mission that underpinning the lifeline of the company, and it is the most important factor to maintain long-term business relationships with customers. Special attention is paid to the quality of every unit of HITEC laser cutting machine. Standard quality control system and team are responsible to insure the product quality in every process with different instruments like laser interferometer and laser power meter. The laser interferometer and laser collimator are used through the mechanical assembling process. In the laser assembling process, the laser power meter and optical microscope are adopted.

NO.2 Packaging & Shipping & Payment

1)Packaging:

Whole film packaging machine; anti-collision package edge; fumigation-free plywood wooden box and pallets with iron binding belt.

2)Shipping:

We cooperate with SINOTRANS company whose experience in the ocean transportation will guarantee your machine safety. We also provide train transport, especially to Russia, Ukraine and other inland countries.

3)Payment:

We support T/T, L/C, VISA, Mastercard payment terms with Alibaba Trade Assurance.

NO.3Warranty and Service

1.Guarantee for 3 years.

2. Maintenance free of charge for 3 years .

3.We will provide the consumable parts at an agency price.

4.24 hours online service, free technical support.

5.Machine has been adjusted before delivery, operation disk is included in the delivery. If there is any other questions, pls kindly tell me.

6.We have manual instruction and CD (Guiding Videos) for software Installation, operation and machine's using and maintenance.

Tag: fiber laser cutting machine price laser cutting machine laser cutting machine price fiber laser laser cutting laser cutter cnc laser cutter fiber metal cutting metal laser cutting machine