Characteristics of handheld fiber laser welding machine equipment

1. Hand-held welding can realize any angle welding to the workpiece, which is suitable for complex welding and spot welding of various devices, and outdoor welding can be realized.

2. Low cost, no need for any welding materials;

3. The welding effect is good, the welding is firm, there will be no de-soldering, and there is no welding spot; The welding seam is beautiful, smooth and without porosity.

4. Good beam quality, fast speed, small thermal deformation, precision and high integration, and will not cause deformation due to heat

5. Wide applicability, such as advertising industry, sheet metal industry, stainless steel doors and windows industry etc.

6. Cost-effective, save labor and welding materials, and consumables are less than 1/10 of traditional welding.

Advantages of Handheld Fiber Laser Welding Machine

1. Fast welding speed, 2~10 times faster than traditional welding.

2. Easy operating and no need training.

3. The welding seam is smooth and beautiful, reducing the follow-up grinding process, saving time and cost.

4. No deformation or welding scar, firm welding of the workpiece.

5. Laser welding has less consumables and long service life.

6. Safer, more environmentally friendly.

Technical Parameters of Fiber Handheld Laser Welding Machine

| Model | HTW-2000w |

| Laser power | 2000W |

| Center wavelength | 1070nm |

| Laser frequency | 50Hz-5KHz |

| Output power stability | <3% |

| Indicator system | Red light |

| Operating environment | Temperature 0-40 ℃, humidity 20% -80% |

| electricity demand | 380V |

| Output fiber length | 10M |

| Welding thickness | 0.5-3mm |

| Air pressure requirements | 4-6Bar |

| Cooling method | Water cooling |

| Machine price | 10000-20500$ |

Its advantages are simple operation, welding seam beautiful, fast welding speed and no consumables. Welding in thin stainless steel plate, iron plate, aluminum plate and other metal materials can perfectly replace the traditional argon arc welding and electric welding technology.

Core accessories of Fiber Laser Welding Machine

| Laser head | Hanwei |

| Control system | Hanwei |

| POWER | 2000W |

| Laser source | Raycus |

| Auto wire feeding device | Yes |

| Cooling way | Industrial water chiller |

| Thickness | 0.5-3mm |

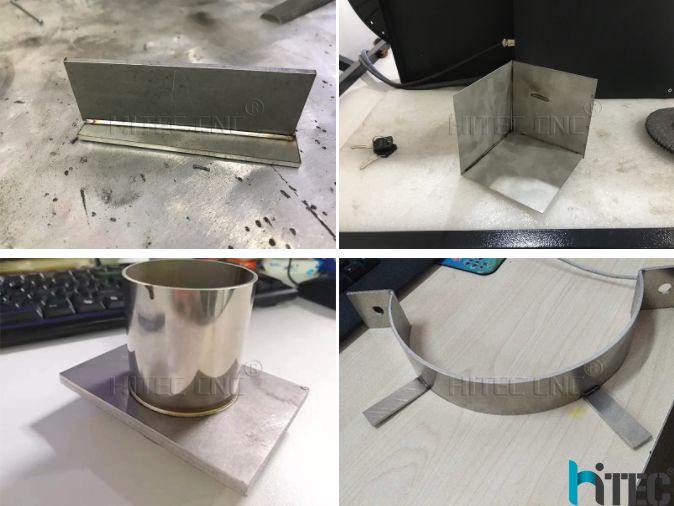

Working Projects of Handheld Laser Welding Machine

Can be widely used in cabinets, kitchen, staircase elevator, shelf, oven, stainless steel door and window guardrail, distribution box, stainless steel home and other industries complex and irregular welding procedures.

Comparison with other welding

| Comparative project | Traditional welding | Fiber laser welding | Our handheld laser welding |

| Weld heat input | very high | low | low |

| Work piece deformation | big | small | small |

| Bonding strength with base metal | general | good | very good |

| Subsequent processing | neeed polish | no or few polish | no or few polish |

| Welding speed | general | 2 times as traditional welding | More than 2 times as traditional welding |

| Applicable material | Stainless steel. Carbon steel. Galvanized sheet | Stainless steel. Carbon steel. Galvanized sheet | Stainless steel. Carbon steel. Galvanized sheet |

| Consumptive material | more | less | less |

| Operation difficulty | complicated | General | simple |

| Safety of the operator | unsafe | safe | safe |

| Impact of environmental protection | Not environmentally friendly | environmentally friendly | environmentally friendly |

| Welding fault tolerance | good | bad | good |

| Swing welding | no | no | yes |

| Light spot width adjustable | no | no | yes |

| Welding quality | inferior | general | good |

Packing of Fiber Laser Welding Machine

| Name | Fiber laser handheld welding machine |

| Packages | Two wooden case packing |

| Machine Packing size | 141x81x132CM |

| Machine Packing weight | 290/324KG |

| Auto wire feeding device size | 71x34x61CM |

| Auto wire feeding device weight | 40/50KG |

| Total | 1.51CBM 330/374KG |

Tag: fiber laser welding machine metal laser welding machine handheld laser welding machine laser welding machine metal welder