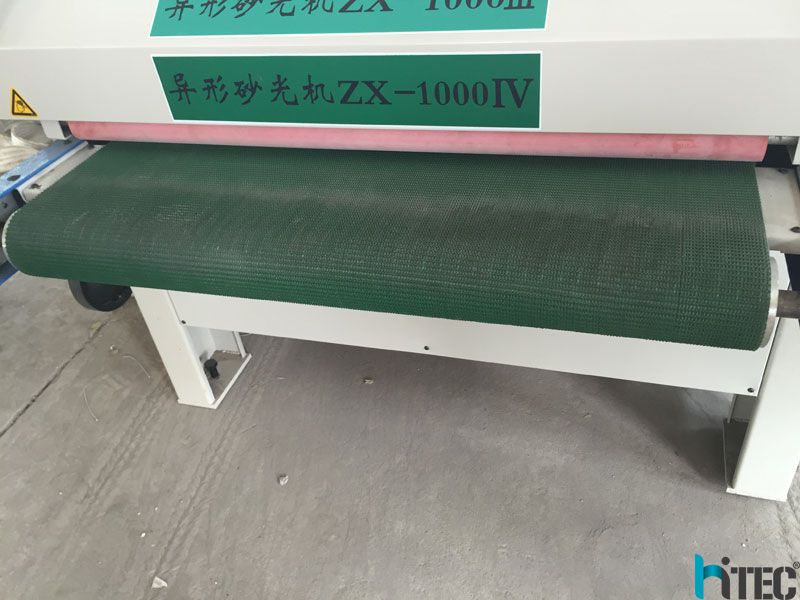

cnc sanding machine for woodworking

cnc sanding machine for woodworking application

cnc sanding machine is mainly used to set thickness.It's preeminent sanding power and stable sanding efficiency are eonomically preferred by the customers to process the original surface of the workpiece.This series is professionally applied to the thickness setting of various boards.

►Wide Belt sanding Function and Characteristics:

(1) It is suitable for calibrating and fine sanding laminate lumber, composite board, particle board, solid wood, panel furniture, bamboo floor, wood door and etc. It is one of the necessary equipment for integrated wood and furniture manufacturing.

(2) The pressing roller protects device to keep the board on the feeding table, which keep the operators safe.

►Wide Belt sanding Installation

(1) Sanding belt automatic centering.

(2) Pneumatic sanding pad

(3) Pressure shoes guarantee feeding work pieces stably

(4) TR internal bearing reduce vibration of belt

(5) Schneider Electrical component

(6) Position indicator wheel ensures precise adjustment of sanding pad

(7) Digital thickness display.

(8) Photoelectric control equipment which control vibrating of abrasive belt along center.

Technology Parameter

| Technical specifications of cnc sanding machine for woodworking | ||

| Max working width | mm | 1300 |

| The shortest processing length | mm | 500 |

| Processing thickness | mm | 3—110 |

| Conveyor speed | m/min | 6—30 |

| Total power | Kw | 63.37 |

| First sand frame motor power | Kw | 37 |

| Second sand frame motor power | Kw | 22 |

| Conveyor motor wattage | Kw | 4 |

| Lifting motor power | Kw | 0.37 |

| First sand frame steel roller diameter | mm | 240 |

| Second sand frame steel roller diameter | mm | 210 |

| Abrasive belt size | mm | 1330*2200 |

| Working pressure | Mpa | 0.6 |

| Dust collection | m^3/h | 9800 |

| Size | mm | 2700*2100*2100 |

| Weight | Kg | 3300 |

Detail Parts of our cnc sanding machine

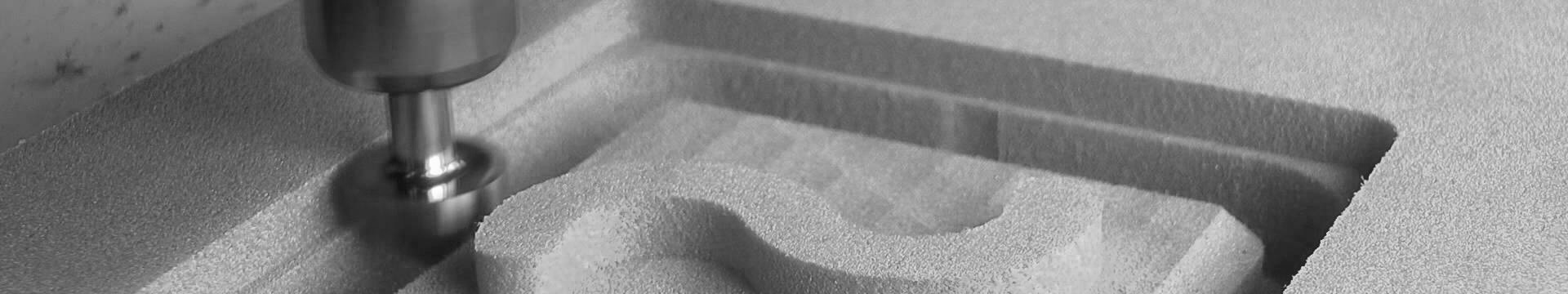

Samples made by our cnc sanding machine

Tag: cnc sanding machine cnc wood sanding machine